Induction Sealing Machine

Product Introduction

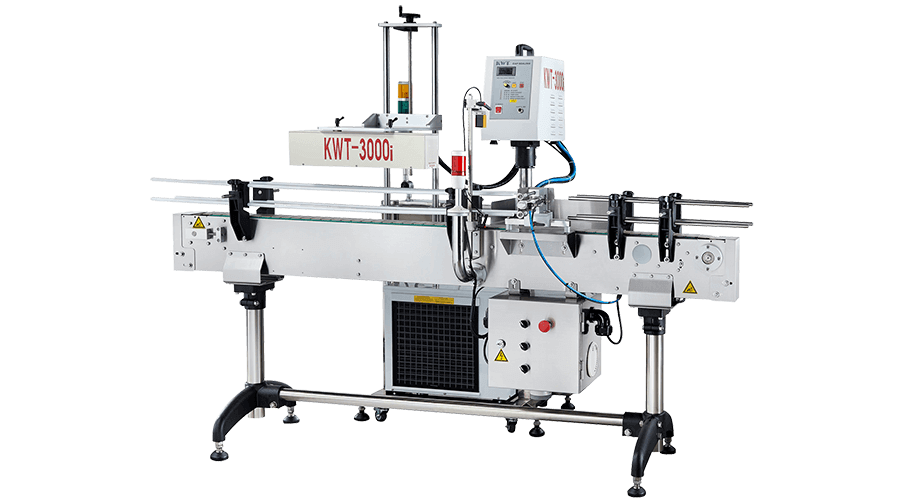

Once containers are filled and capped, they undergo induction sealing which uses a non-contact heating to weld a foil laminate to the lip of bottles and jars. The containers with caps move along a conveyor, passing under and induction cap sealer for the sealing operation.

Advantage of induction sealerThe induction sealing process offers several advantages, making it a popular choice for sealing jars and bottles. Some of the key advantages include:

- Tamper-Evident Seals: Induction sealing creates a hermetic seal, which helps preserve the product’s freshness and prevents leaks. It also provides tamper-evidence, ensuring the completely of the product until it reaches the end consumer.

- Non-Contact Heating: Induction sealing is a non-contact method, meaning the sealing process does not require physical contact between the sealing equipment and the container’s lid. This eliminates the risk of contamination.

- Efficient and Fast: Induction sealing is a rapid sealing process, allowing for high-speed production lines. The seals are formed quickly and consistently, enhancing production efficiency and reducing downtime.

- Versatility: The process is suitable for a wide range of container types, sizes and materials. It can handle various cap styles, making it adaptable to different packaging requirements.

- Longer Shelf Life: Due to its effective sealing capabilities, induction sealing can extend the shelf life of products by preventing spoilage, oxidation and moisture ingress.

KWT helps many of lubricants, beverage, food and dairy packagers implement induction sealer into their production lines. Seek advice from KWT experienced application specialists to optimize the induction sealing process for your products.