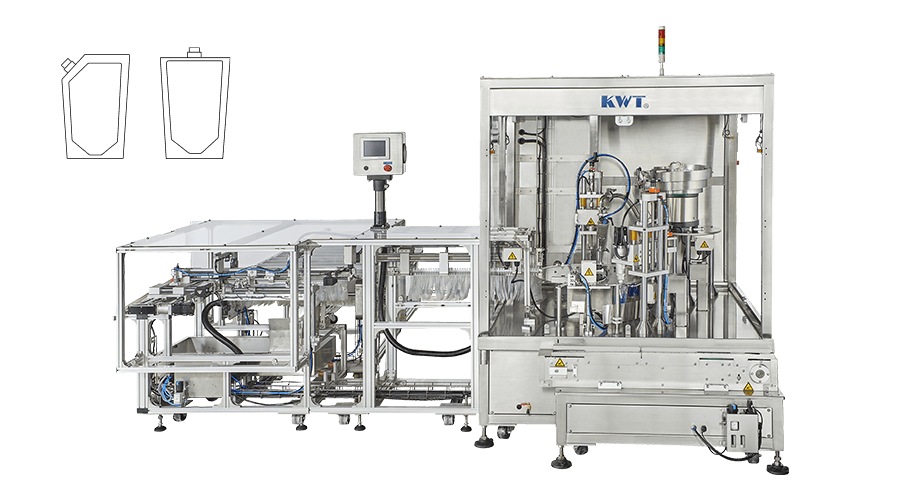

Pre-Made Spouted Pouch Filling and Capping Machine

Product Introduction

Fill and cap spout pouches of liquid product automatically with this advanced pouch filling machine. Engineered specifically for pre-made top ro corner spout pouches, this versatile system fills liquid products through the spout with precision and efficiency. The machine is ideally suited for both food processing and chemical manufacturing applicaitons, ensuring reliable performance across industries while maintaining excellent product quality and minimizing leakage rates.

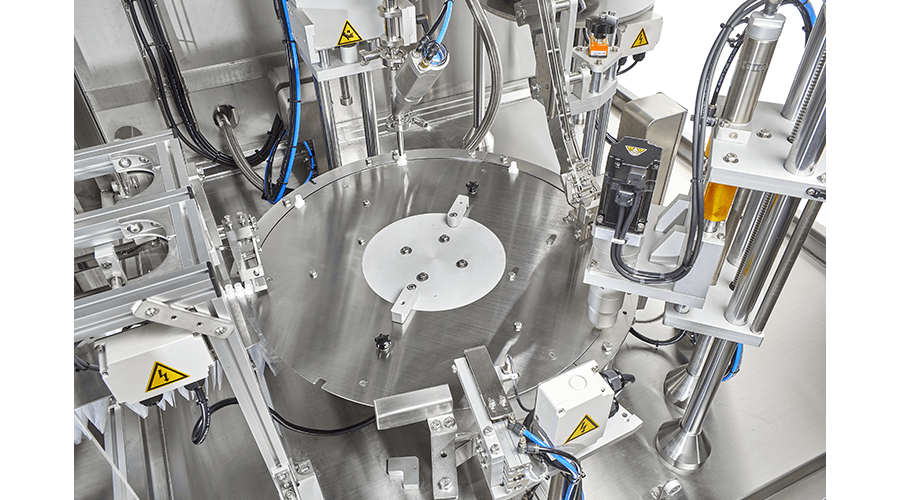

The filling system features a high-precision piston pump controlled via servo technology for accurate dispensing and superior filling precision. Premium food grade stainless steel construction throughout ensures durability, hygiene, and compliance with industry standards. This robust build quality contributes to the machine's long-term cost-effectiveness and ability to maintain consistent daily output.

The machine's design focuses on maximizing productiion efficiency while minimizing waste. Its precision filling capabilities result in reduced leakage rates and improved product quality, making it an ideal choice for manufacturers looking to optimize their packaging processes.

With its ability to handle different pouch sizes and various product types, including juice, sauce, puree and shampoo, this pouch filling machine offers flexibility for diverse production needs. The system's ease of use, combined with its high daily output capacity, makes it a valuable asset for businesses aiming to streamline their packaging operations and improve overall productivity.