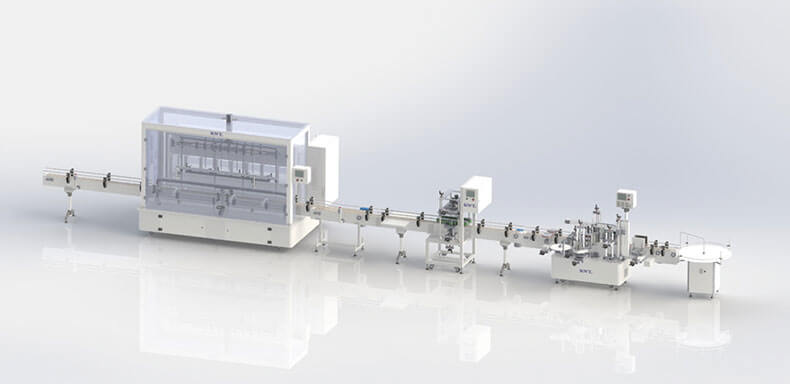

Detergent Filling Line

Filling Range

500ml-5L

Nozzles

4 to 8

Speed

≦40 pcs/min

Optimized 40 BPM Detergent Filling Line: Precision and Versatility for Modern Production

In the fast-paced home care and household chemical industry, manufacturers face increasing demands for flexibility, efficiency, and cost savings. KWT's optimized 40 BPM detergent filling line delivers a comprehensive solution tailored for low-viscosity, foaming liquids like laundry detergents, dish soaps, and specialty cleaners. Engineered with cutting-edge technology, this automatic detergent production line ensures seamless handling of diverse bottle shapes and closure types while minimizing downtime and maximizing ROI.

Today's detergent market requires agility to adapt to frequent product variations and packaging changes. Our turnkey detergent filling solution integrates an inline rotary lobe pump filling machine, a semi-automatic side-wrap capping machine, and a front/back labeler with wrap-around capabilities. Designed specifically for the unique challenges of foaming detergents, it maintains product quality and aesthetic appeal from start to finish.

Key benefits include

- Foam Control: Bottom-up filling nozzles submerge below the liquid surface to reduce splashing and foaming, ensuring clean, precise fills.

- Universal Compatibility: Handles round, oval, or square bottles without costly change parts, ideal for liquid detergent production lines.

This line stands out in the competitive landscape by offering a smaller footprint and lower initial investment compared to traditional setups, making it perfect for medium-scale operations seeking scalable growth.

Downtime can erode profits in high-mix production environments. KWT's detergent filling line features quick-changeover technology that allows full transitions in under 30 minutes, cutting setup time by up to 50%:

- Handwheel Adjustments: Intuitive counters enable fast bottle size switches, reducing idle periods and boosting overall equipment effectiveness (OEE).

- Recipe Management System: Touchscreen interface for saving and recalling SKU parameters instantly, streamlining operations for busy production teams.

By reducing downtime to under 30 minutes, KWT empowers manufacturers to maintain high productivity. The combination of precision hardware adjustments and instant digital recipe recalls ensures that variety never comes at the cost of profitability.

Inline filling remains the preferred choice for detergent applications due to its proven advantages over other methods:

- Versatility: Accommodates various container shapes and sizes without extensive modifications.

- Ease of Maintenance: Open architecture provides direct access to components, simplifying cleaning and repairs.

- Scalability and Cost-Effectiveness: Compact design lowers upfront costs and accelerates return on investment, especially for growing businesses.

In an era where green manufacturing is key, our system also supports waste reduction by optimizing fill accuracy and minimizing overflows—aligning with industry shifts toward sustainable detergent production.

Inline filling remains the preferred choice for detergent applications due to its proven advantages over other methods:

For a quick overview, here's a breakdown of the core capabilities:

| Feature | Description | Benefit |

| Capacity | Consistent 40 Bottles Per Minute (BPM) | Reliable output for medium-volume runs |

| Filling Method | Flow meter or rotary lobe pump | Reduces foaming and ensures precise dosing |

| Capping System | Semi-auto side-wrap with twin belts | Handles complex closures like triggers and pumps |

| Labeling | Front/back with wrap-around station | Suitable for different size of bottles |

| Changeover Time | Under 30 minutes with hand-wheel and touchscreen | Boosts efficiency in high-mix environments |

| Compatibility | Laundry liquids, dish soaps, household cleaners; round/oval/square bottles | Versatile for the home care market |

| Construction | Main construction is made by stainless steel | Durable, easy-to-maintain, and hygienic |

KWT's detergent filling line is more than equipment—it's a strategic partner for overcoming production challenges and driving growth. With proven results in reducing downtime and enhancing flexibility, it's the ideal choice for manufacturers aiming for excellence.

Contact our team today for a personalized demo, quote, or to download our free guide on optimizing liquid filling lines. Let's discuss how this solution can transform your operations—reach out at sales@kwt-auto.com.tw.

Key Features

- This type of rotary lobe pump is suited for homecare product.

- Robust construction in stainless steel.

- Mitsubishi PLC controlled with touch screen panel.

- Easy adjusting hand wheels for quick changeover.

- 50 job memory for easy set-up and recall.

- Neck grabber for different sizes of container.

- Capable capping type: plastic screw cap, trigger cap, pump cap.

- Manually apply caps.

- Capping roller utilize servodrive to control the capping process and to quick change over to another format.

- Labeling – automatic labeling machine to label flat / oval / cylindrical containers (front / back / wrap-around).

Options

- Filling Machine

- Safety Guard

- Nozzle up & down action driven by servo motor

- Filling nozzle (Dia. 12.7mm) for small neck

- Liquid feeding pump.

- Conveyor upgrade

- Capping Machine

- Conveyor upgrade

- Labeling Machine

- Angle adjustment of labeling head

- Transparent Label Sensor

- Upgrade to oval shape bottle alignment

- Push & Press attachment

- Coding system: hot stamp or thermal-transfer printer

- Conveyor upgrade

- Accumulation turn table

Specifications

| Nozzles | Up to 8 pcs |

|---|---|

| Fill Volume Range | 500ml-5L |

| Filling Assembly | Rotary Lobe Pump |

| Nozzle Size | Dia. 19mm (Standard) |

| Container Thickness Range | 40mm-150mm |

| Container Length Range | 50mm-200mm |

| Container Height Range | 140-350mm |

| Capping Machine | 130 / 130AS |

| Number of Capping Roller | 4 capping roller |

| Label Type | Pressure Sensitive Label |

| Label Size | 20-220mm in height, 20-250mm in length |

| Label Roll Size | I.D. 76 mm ,O.D. 350 mm (Max.) |

| Conveyor Width | 82.5 , 114 , 152mm |

| Conveyor Length | 13,085mm |