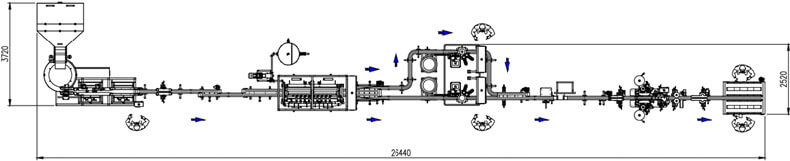

Dual Lane Detergent Filling Line

Filling Range

250ml-5L

Nozzles

10

Speed

≦70 pcs/min

A full line for bottle unscrambler, filling, capping, labeling and secondary packaging machine. Works with various types and shapes of bottle, 10 filling nozzles in dual lane ensure continuous work without stop for saving the waiting time. Dosing range is from 250ml to 5000ml, the productivity up to 70 pcs /min. Utilize the flow meter to fill chemical product with foamy based. A perfect solution for the household industry thanks to the capability of dosing dish wash, softener, laundry sanitizer, bathroom cleaner.

Key Features

- Bottle unscrambler is capable of handling cylinder or square bottles.

- Magnetic flow meter is suited for homecare product.

- Robust construction in stainless steel.

- Mitsubishi PLC controlled with touch screen panel.

- Easy adjusting hand wheels for quick changeover.

- 50 job memory for easy set-up and recall.

- Neck grabber for different sizes of container.

- Capable capping type: plastic screw cap.

- Auto Pick & Place device is designed to handle most cap types, and driven by servo motor.

- Capping chuck with servo drive for adjustable torque values.

- Labeling – automatic labeling machine to label flat / oval / cylindrical containers (front / back / wrap-around).

Options

- Bottle Unscrambler

- Safety Guard

- Orientation Device

- Conveyor upgrade

- Filling Machine

- Safety Guard

- Nozzle up & down action driven by servo motor

- Filling nozzle (Dia. 12.7mm) for small neck

- Liquid feeding pump

- Conveyor upgrade

- Bottle feeding table

- Capping Machine

- Safety Guard

- Cap hopper & elevator

- Vibrator bowl, cap chute, gripper and chuck for different size of cap

- Bottle star-wheel for different size of bottle

- Conveyor upgrade

- Inspection: missing cap / cock cap / missing foil liners

- Labeling Machine

- Angle adjustment of labeling head

- Transparent Label Sensor

- Upgrade to oval shape bottle alignment

- Push & Press attachment

- Coding system: hot stamp or thermal-transfer printer

- Conveyor upgrade

Specifications

| Nozzles | 10 nozzles in dual lane |

|---|---|

| Fill Volume Range | 250ml-5L |

| Filling Assembly | Magnetic Flow Meter |

| Nozzle Size | Dia. 19mm (Standard) |

| Container Thickness Range | 40mm-150mm |

| Container Length Range | 50mm-200mm |

| Container Height Range | 140-350mm |

| Capping Machine | 182AS x 2 / 130AS x 2 |

| Label Type | Pressure Sensitive Label |

| Label Size | 20-180mm in height, 20-250mm in length |

| Label Roll Size | I.D. 76 mm , O.D. 350 mm (Max.) |

| Conveyor Width | 82.5 , 114 , 152mm |

| Conveyor Length | 26,440mm |