Laundry Detergent Filling Line

Filling Range

3500ML

Nozzles

10

Speed

20 pcs/min

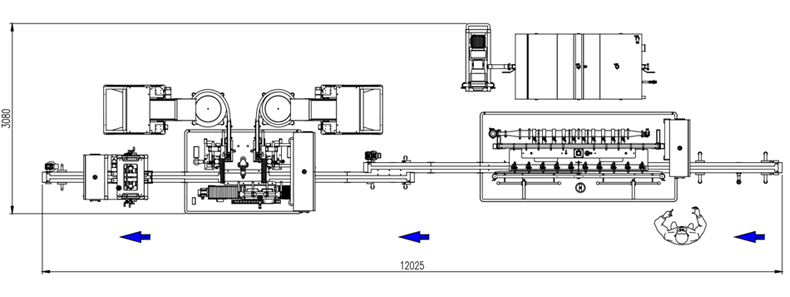

Automatic production line for filling and capping of liquid household products: A complete line solution for the packaging industry. This advanced machinery utilizes cutting-edge mass flow meter technology to accurately fill chemical and foamy products with precision. The KWT FL Series volumetric filler machine , a versatile auto filling machinery delivers exceptional performance, capable of handling water-think liquids, semi-viscous substances, and foamy liquids with accuracy at an efficient speed of 20-24 bottles per minute.

This state-of-the-art filling machinery is part of a comprehensive production line that inlcudes bottle unscramblers and labeling machines, offering a holistic approach to packaging. The system features user-friendly design with a touch screen panel, enabling quick and seamless product changeover time between different items. The entire process requires less than 30 minutes for a complete transition, making it an ideal solution for both the household and packaging industries.

Key Features

- Mass flow meter is suited for homecare product.

- Robust construction in stainless steel.

- Mitsubishi PLC controlled with touch screen panel.

- Easy adjusting hand wheels for quick changeover.

- 50 job memory for easy set-up and recall.

- Neck grabber for different sizes of container.

- Capable capping type: spout cap & plastic screw cap.

- Fast bottle transportation system.

- Auto Pick & Place device is designed to handle most cap types, and driven by servo motor.

- Capping roller utilize servodrive to control the capping process and to quick change over to another format.

Options

- Filling Machine

- Safety Guard

- Nozzle up & down action driven by servo motor

- Filling nozzle (Dia. 12.7mm) for small neck

- Liquid feeding pump

- Spout Cap Placing Machine

- Safety Guard

- Cap hopper & elevator

- Vibrator bowl, cap chute, gripper for different size of cap

- Bottle finger for different size of bottle

- Capping Machine

- Safety Guard

- Cap hopper & elevator

- Vibrator bowl, cap chute, gripper for different size of cap

- Inspection: missing cap / cock cap

Specifications

| Nozzles | Up to 10 pcs |

|---|---|

| Fill Volume Range | 1000ml-5000ml |

| Filling Assembly | Mass Flow Meter |

| Nozzle Size | Dia. 25.4 mm |

| Container Thickness Range | 80mm-160mm |

| Container Length Range | 120mm-200mm |

| Container Height Range | 140-330mm |

| Capping Machine | 150AS / 130S |

| Number of Capping Roller | 4 capping roller |

| Conveyor Width | 152mm |

| Conveyor Length | 12,025mm |