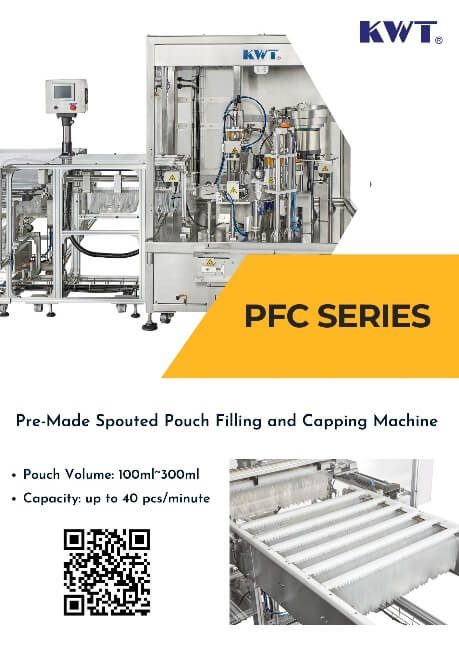

KWT Launches Spout Pouch Filler and Capper

During this year's Taipei Pack, KWT is presenting newly developed spout pouch filling and capping technology for the first time.

KWT's one-lane automatic center spout pouch filling and capping machinery stands out as prime solution for enhancing the efficiency of liquid product packaging. With the ability to handle the latest convenient spouted pouch designs, this packaging equipment is geared towards boosting productivity and decreasing operational costs. Its modular structure and intuitive touch screen facilitate effortless maintenance and operational management, empowering business to achieve optimal performance with a single operator.

Using a spout pouch offers several compelling reasons for manufacturers and businesses in various industries.

- Sustainability: Many spout pouch filling and capping machines are compatible with eco-friendly and recyclable materials, contributing to more sustainable packaging practices.

- Convenience and Portability: Spout pouches are lightweight and easy to carry, making them convenient for consumers on the go. The built-in spout allows for easy pouring and dispensing, eliminating the need for additional utensils.

- Reduced Packaging Weight and Waste: Spout pouches often require less material compared to traditional rigid packaging, which reduces overall packaging weight and waste. This contributes to lower shipping costs and smaller environmental footprint.

- Less Risk of Contamination: Spout pouches reduce the risk of contamination since the contents can be dispensed without direct contact with the packaging interior. This is particularly important for food and beverages.

The advantages of spout pouches make them an attractive packaging option for both manufacturers and consumers. They address various packaging needs while offering benefits such as sustainability and convenience.

Visit KWT to see the machine in person.