Robotic Unscrambler: Revolutionizing Bottle Handling in Packaging Applications

Antiquated technology significantly hampers progress in industries prioritizing swift production transitions, versatile multi-format capabilities, and the speed and efficiency of manufacturing processes. In the realm of packaging applications, traditional bottle handling systmes often struggle to meet modern production demands, leading to decreased productivity and increased operational costs.

View the video of KWT robotic bottle unscrambler how we’ve assisted clients in optimizing production, ensuring the competitiveness of their products in today's fast-paced manufacturing environment.

Our innovative robotic bottle unscrambler represents a breakthrough in bottle unscrambling technology, accommodating bottles of any shape and size (round, square, oval, transparent and colored), without the need for specific parts. This intelligent transport system automatically adjusts for bottle size variations, enhancing production flexibility and versatility, leading to improved capacity and throughput rate.

- Exceptional Versatility: Work with various shapes of plastic bottes and containers, including round, square, oval, transparent and colored

- Advacned Artificial Vision: Our visual verification system ensures consistent container orientationn and positioning every time

- Size Accommodation: Handles a wide range of container formats from 500ml to 5L bottles

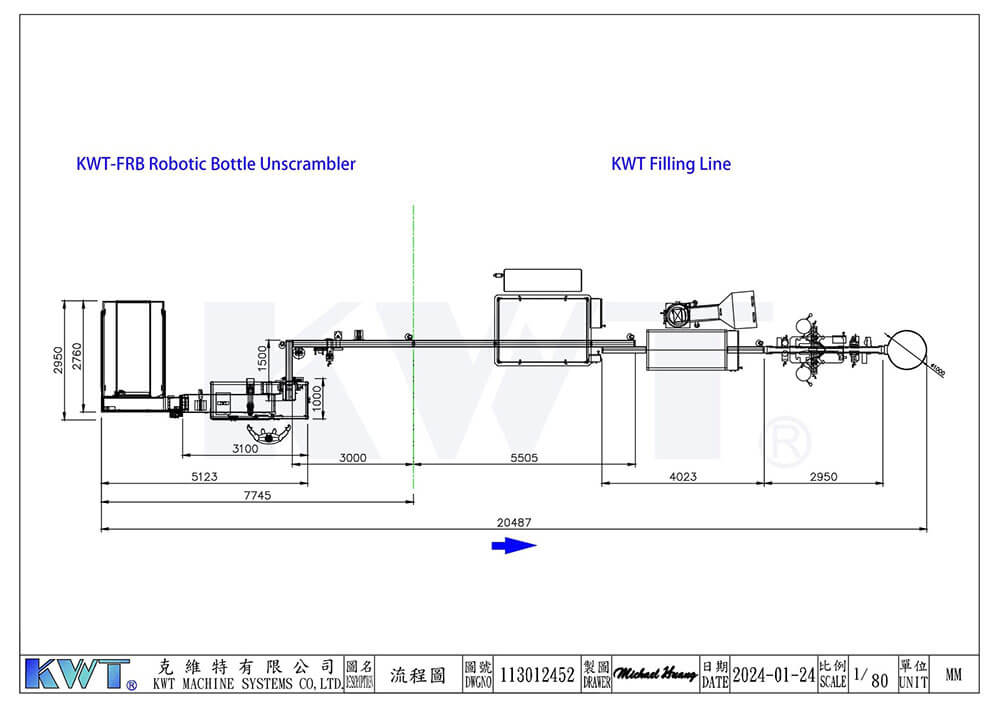

- Seamless Integration: The robotic unscrambler integrates effortlessly with packaging line, supporting and enhancing existing operations in the customer's plant

- User-Friendly Interface: Our multi-touch panel not only facilitates automatic format changeovers but also allows the operator to add new formats easily through the touchscreen controller

- Impressive Output: Achieves throughput rates 40 pcs/min for 1L bottles, 20 pcs/min for 5L bottles

Advanced Technology for Efficient Bottle Handling

Our robotic unscrambler utilizes cutting-edge pick-and-place robots, including OMRON robots, to ensure precise and rapid bottle handling. The system employs a vacuum system with suction pads to securely grip and manipulate bottles, ensuring they are placed in stable position on the exit conveyor.

Felxibility and Ease of Use

One of the key advantages of our robotic unscrambler is its ability to handle multiple container formats with minimal downtime. the incorporatiion of advanced artificial vision technology ensures that bottle is correctly oriented, before being placed on the conveyor belt. This intelligent infeed metring system minimizes errors and maintains consistent quality throughout the packaging process.

Integration and Control

Our robotic unscrambler seamlessly integrates into existing packaging lines. The system's OMRON PLC ensure smooth operation and easy integration with other equipments. The multi-touch control panel provides intuitive access to all system functions, allowing operators to adjust settings and initiate automatic format changeovers with ease. This user-friendly interface contributes to reduced training time and improved operational efficiency.

We extend an invitation to our Taichung factory, where our engineers and technical advisors will gladly address any inquiries and provide a demonstration of the robotic unscrambler in action. Experience firsthand how this innovative solution can transform your packaging operations, improving efficiency and flexibility in your production line.