Boosting Manufacturing Efficiency with Lubricant Filling Technology

In today’s fast-paced manufacturing environment, efficiency isn’t just a goal – it’s a necessity. As demand for industrial and automotive lubricants continues to grow globally, manufacturers ae turning to automation and advanced packaging machinery to stay competitive.

Why Efficiency Matters in Lubricant Packaging

Lubricants such as engine oils, hydraulic fluids and gear oils are essential for automotive performance. However, their thick, sticky consistency poses challenges during packaging. Manual or outdated filling and capping processes often lead to:

- Inaccurate fill volumes

- Wasted product

- Spillage and contamination

- Bottlenecks in production lines

Modern liquid filling machines address these issues by offering speed, precision and reliability, resulting in measurable efficiency gains. A well-designed filling production line ensures that every stage of the packaging process is optimized for efficiency and quality:

-

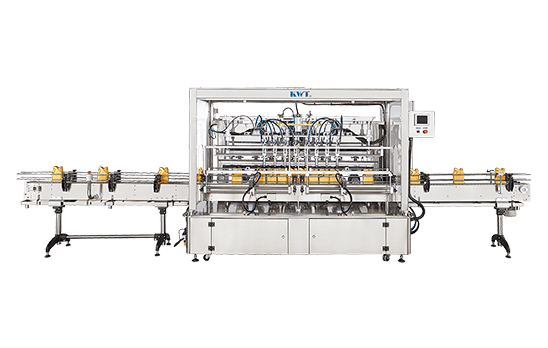

Precision Filling Machines

Whether you’re packaging full synthetic oil or high-performance additives, automatic filling machines with gear pump or flowmeter fillers ensure consistent volumes across a wide range of container sizes.

- Gear Pump Fillers – Ideal for lubricant, offering precise volume control

- Flowmeter Fillers – Provide various container sizes and volumes

-

Automatic Capping Machines

Once filled, containers must be sealed securely to prevent leakage. Bottle capping machines provide torque control, minimizing human error. Some advanced systems may include induction sealing for an extra layer of protection.

-

Labeling Machines

Labeling system apply brand and regulatory labels accurately, often integrated with ink jet printer or laser coders to ensure that batch numbers and production dates are clear and compliant.

-

Inspection Systems

Advanced lines include vision systems and check weighers to verify underfills, missing label, label placement and missing caps. This helps manufacturer avoid costly recalls or customer complaints.

-

Secondary Packaging

End-of-line solutions may include case packers, cartoning machines and palletizers to further reduce manual handling. An overwrapping machine can provide additional protection for retail-ready packaging.

Key Benefits of Lubricant Filling Technology

- Stable throughput: Modern filling, capping and labeling systems fill hundreds to thousands of containers per hour, ensuring production capacity stability.

- Improved Accuracy: Minimizes product giveaway and reduces the cost of rework.

- Reduced Downtime: Quick change-over keep production running smoothly.

- Lower Labor Cost: Automation reduces reliance on manual labor, improving consistency and lowering operational costs.

Choosing the Right Filling Solution

The best compact filling line for your facility depends on several factors:

- Container Size

- Filling volume range

- Required production speed

- Space constraints

It’s important to work with experienced equipment providers who can tailor the system to your specific production requirements. Many modern filling production lines incorporate a PLC control system for seamless operation and easy adjustment.

Additional components that may enhance your lubricant packaging line include:

- Bottle unscrambler for efficient container handling

- Piston filling machine for hightly viscous products

- Collection table for smooth product flow

- Safety warning device to protect operators

For smaller operations or specialty products, semi-automatic filling equipment can offer a balance of efficiency and flexibility.

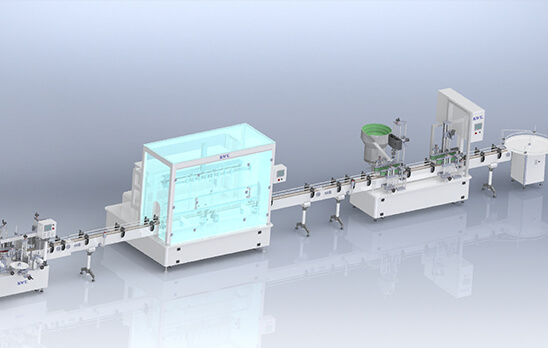

Investing in modern lubricant filling technology is more than an upgrade – it’s a strategic move. With KWT’s advanced filling solutions, you can automate your production line to enhance product consistency, minimize losses, and position your operation for scalable growth. Whether you’re expanding capacity or modernizing an aging system, KWT’s liquid filling machins and comprehensive packaging solutions ensures your production line is ready to meet the demands of today – and the challenges of tomorrow.

From essential oil filling to industrial lubricants, a well-designed filling production line with leak-proof design and efficient filling and capping capabilities can significantly boost your manufacturing efficiency. By incorporating the right combination of automatic filling machines, bottle capping machines, and advanced labeling systems, you can create a streamlined process that maximizes output while maintaining the highest quality standars.

♦ KWT Advanced Lubricant Filling Line