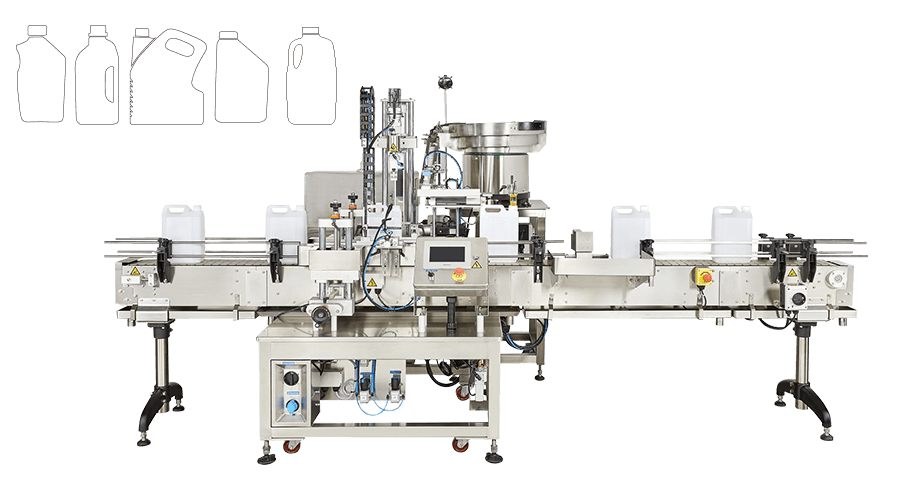

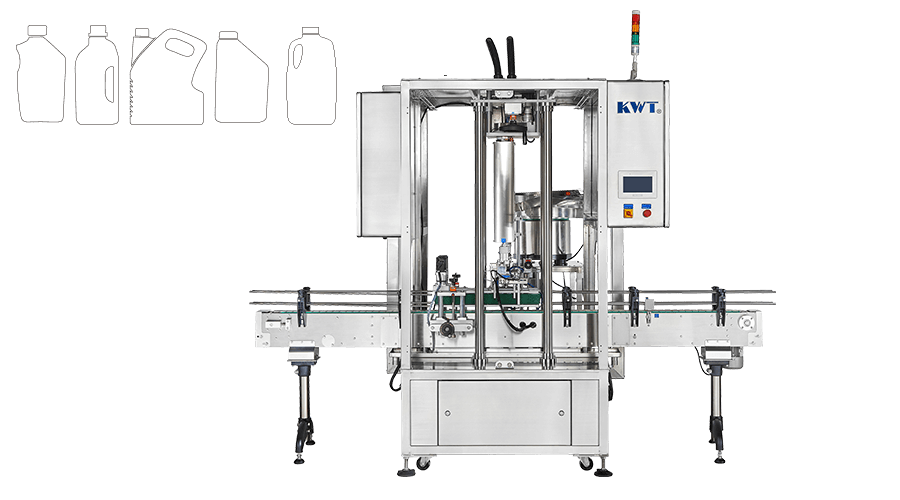

KWT-151AL Auto Capping Machine

Product Introduction

The KWT-151AL is an advanced automatic capping machine designed for efficient and precise screw capping in various packaging applications. This versatile capping system enables secure cap gripping for accurate placement and tightening onto containers. As a crucial component of packaging machinery in production lines, it supports a wide range of container sizes and shapes. The automatic capper features a side belt to stabilize containers during the capping process, ensuring smooth operation and consistent results.

Advanced Capping Equipment

Advanced Capping Equipment

The KWT-151AL bottle capping machine is designed to meet the demands of modern packaging production lines. The machine's cap placement mechanism ensures accurate positioning, while the integrated cap tightener applies the correct amount of torque for a secure seal.

Efficient and Flexible Operation

This automatic capping machine is engineered for high-speed operation, capable of processing up to 40 bottle per minute. The quick-change capping gripper allow for easy adaptation to different cap types, significantly reducing downtime during product changeovers. The machine's flexibility makes it suitable for a wide range of industries, including food packaging, chemical packaging and cosmetic applications.

User-Friendly Interface and Control

The PLC-controlled system with a touch screen panel provides operators with easy access to all machine settings. This intuitive interface allows for quick adjustments, ensuring consistent quality control throughout production runs. The ability to store up to 50 product profiles in memory further streamlines operaitons and reduces setup time for recurring products.

Versatile Application

This automatic capper is suitable for a wide range of container types, including glass bottles and plastic containers. Its adjustable settings accommodate various bottle heights and widths, making it a versatile solution for diverse packaging needs. Whether used for screw capping, cap pressing, or other closure applications, the KWT-151AL delivers consistent and reliable results.

By incorporating advanced features such as torque control, efficient cap feeding systems, and quick changeover capabilities, the KWT-151AL automatic capping machine stands as valuable asset in any packaging production line, offering a perfect balance of speed, precision and flexibility.

Efficient and Flexible Operation

This automatic capping machine is engineered for high-speed operation, capable of processing up to 40 bottle per minute. The quick-change capping gripper allow for easy adaptation to different cap types, significantly reducing downtime during product changeovers. The machine's flexibility makes it suitable for a wide range of industries, including food packaging, chemical packaging and cosmetic applications.

User-Friendly Interface and Control

The PLC-controlled system with a touch screen panel provides operators with easy access to all machine settings. This intuitive interface allows for quick adjustments, ensuring consistent quality control throughout production runs. The ability to store up to 50 product profiles in memory further streamlines operaitons and reduces setup time for recurring products.

Versatile Application

This automatic capper is suitable for a wide range of container types, including glass bottles and plastic containers. Its adjustable settings accommodate various bottle heights and widths, making it a versatile solution for diverse packaging needs. Whether used for screw capping, cap pressing, or other closure applications, the KWT-151AL delivers consistent and reliable results.

By incorporating advanced features such as torque control, efficient cap feeding systems, and quick changeover capabilities, the KWT-151AL automatic capping machine stands as valuable asset in any packaging production line, offering a perfect balance of speed, precision and flexibility.