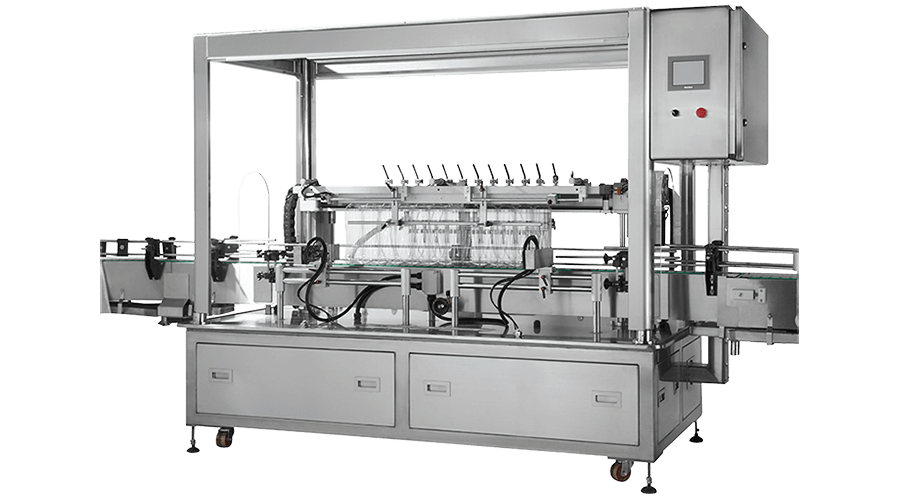

Inline Bottle Rinser

Product Introduction

KWT bottle rinsers, including air rinsers and water rinsers, are essential packaging machinery used in the bottling industry to evacuate dust and foreign particulates from the inside of glass and plastic bottles, ensuring through bottle cleaning prior to the filling process. Our bottle wasing equipment is designed with a focus on flexibility, versatility and simplicity to meet various container types and productions runs.

The mechanical components of our rinsers allow for easy handling of many container shapes and sizes with simple changeover parts. Advanced touchscreen interfaces and PLC controls on our rinsers provide the ability to store multiple programs, significantly decreasing changeover times and optimizing production runs.

KWT provides water and air cleaning systems that are crucial in food filling applications to ensure consumer safety and maintain strict hygiene protocols. The bottle rinser can utilize compressed air and cleaning solutions to remove dust or sanitize your containers prior to filling, adhering to the highest standards of product quality and regulatory compliance.

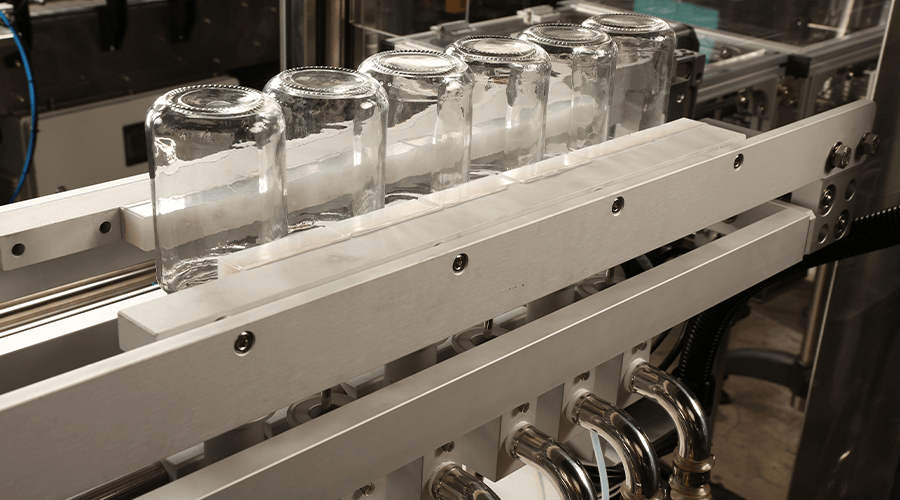

KWT's automatic bottle rinser comes complete with conveyor systems, bottle clamping assemblies and cleaning nozzles, those are made by plastic, alluminum and stainless steel. This robust constructiion ensures durability and longevity in demanding bottling plant environments.

The mechanical components of our rinsers allow for easy handling of many container shapes and sizes with simple changeover parts. Advanced touchscreen interfaces and PLC controls on our rinsers provide the ability to store multiple programs, significantly decreasing changeover times and optimizing production runs.

KWT provides water and air cleaning systems that are crucial in food filling applications to ensure consumer safety and maintain strict hygiene protocols. The bottle rinser can utilize compressed air and cleaning solutions to remove dust or sanitize your containers prior to filling, adhering to the highest standards of product quality and regulatory compliance.

KWT's automatic bottle rinser comes complete with conveyor systems, bottle clamping assemblies and cleaning nozzles, those are made by plastic, alluminum and stainless steel. This robust constructiion ensures durability and longevity in demanding bottling plant environments.

For more details about our packaging machinery and liquid packaging solutions, please contact KWT. If you have specific requirements for a bottle rinser, our products can certainly meet and exceed your expectations. The KWT-8W and 8A series are Inline Bottle Rinsers, capable of utilizing compressed air or wasing liquid to clear debris from your containers prior to the filling process.

Our bottle rinsers can be easily integrated into existing or new bottle packaging systems, enhancing your overall packaging process. KWT's automatic bottle rinser is a PLC-operated machine controlled by an intuitive touchscreen interface, provding the ability to store multiple settings for different container types and cleaning requirements. The bottle rinser can be set up in 30 minutes and allows for quick changeovers, optimizing your production efficiency.

Our bottle rinsers can be easily integrated into existing or new bottle packaging systems, enhancing your overall packaging process. KWT's automatic bottle rinser is a PLC-operated machine controlled by an intuitive touchscreen interface, provding the ability to store multiple settings for different container types and cleaning requirements. The bottle rinser can be set up in 30 minutes and allows for quick changeovers, optimizing your production efficiency.