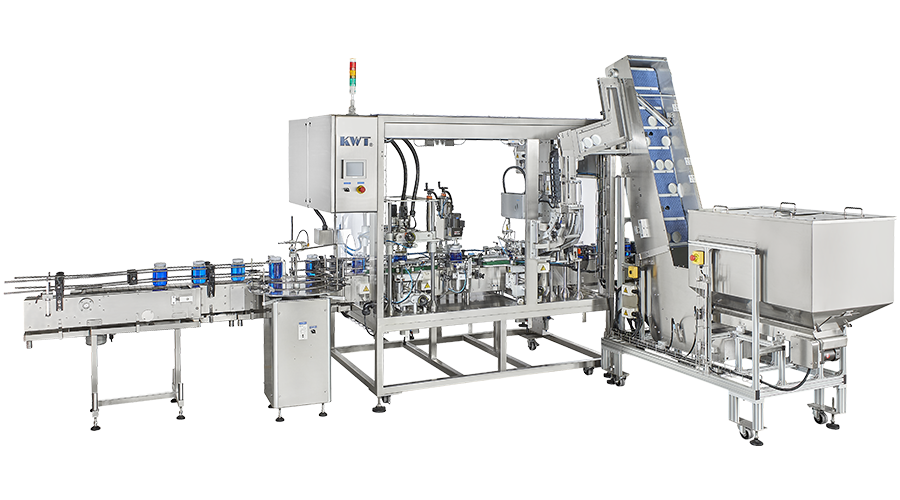

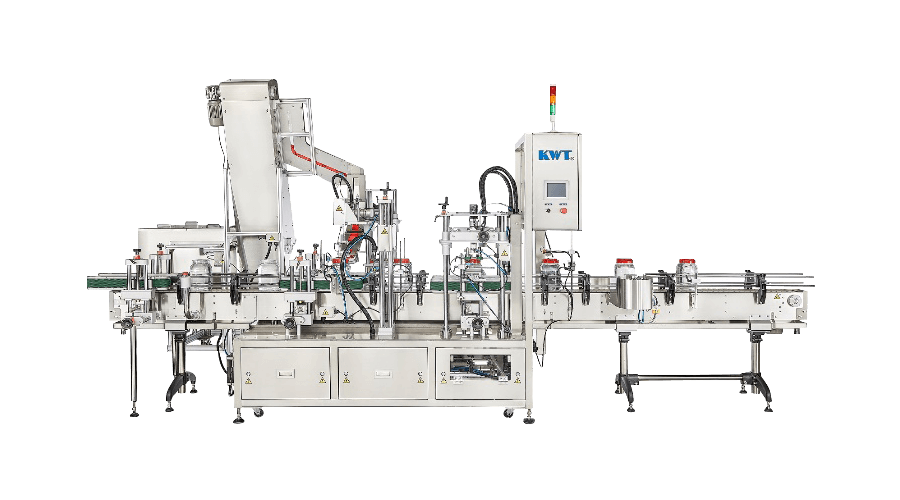

KWT-130AS Capping Machine for Large Container

Product Introduction

The KWT-130AS capping machine is a engineered specifically for large container applications, featuring an advanced pick & place mechanism. This system efficiently retreives caps from the delivery chute and precisely positions them onto containers. The subsequent capping roller operation ensures secure and precise tightening, guaranteeing optimal seal integrity for every container processed.