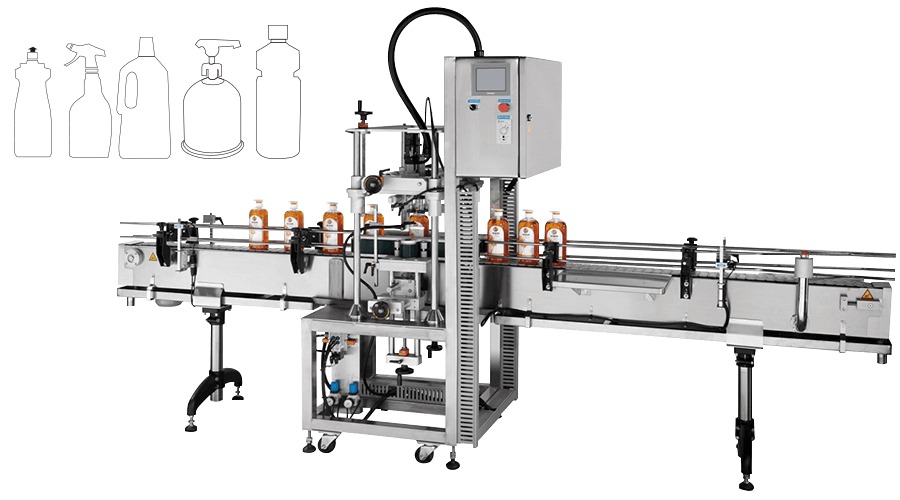

KWT-130S Semi-Auto Side-Wrap Capper

Product Introduction

The KWT-130S is semi-auto bottle capper designed to efficiently secure various types of caps, including trigger caps, pump caps, spray caps and regular caps. This versatile bottle capping equipment excels in handling spray bottles, trigger pump bottles and standard containers with precision and speed.

The KWT-130S capping machine simplifies the capping process. Operators place caps onto containers and the advanced servo capping heads handle the torque applicaiton automatically. This pump capper and trigger capper combination offers flexibility in production lines.

The KWT-130S offer a perfect blend of versatility, precision and efficiency. Whether you're dealing with trigger spray bottles, pump containers or standard caps, this advanced bottle capping equipment and adaptable design, the KWT-130S is an invaluable asset for any production line seeking to optimize their capping processes.