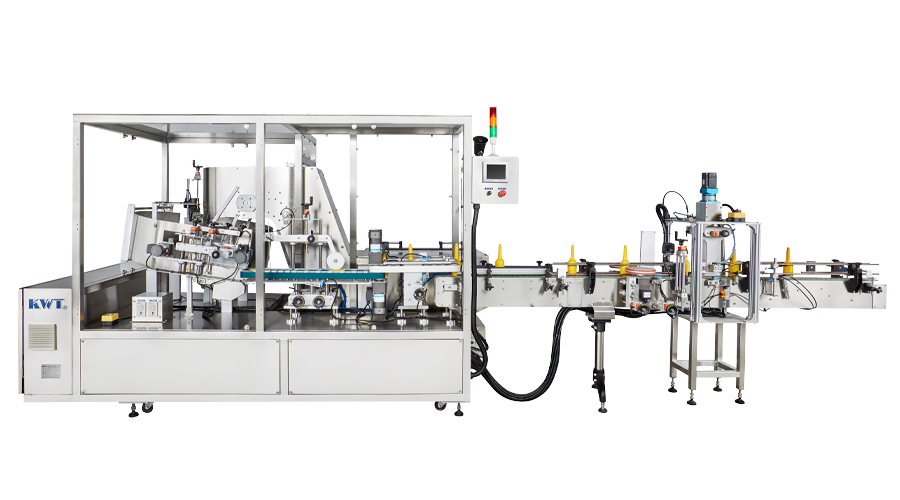

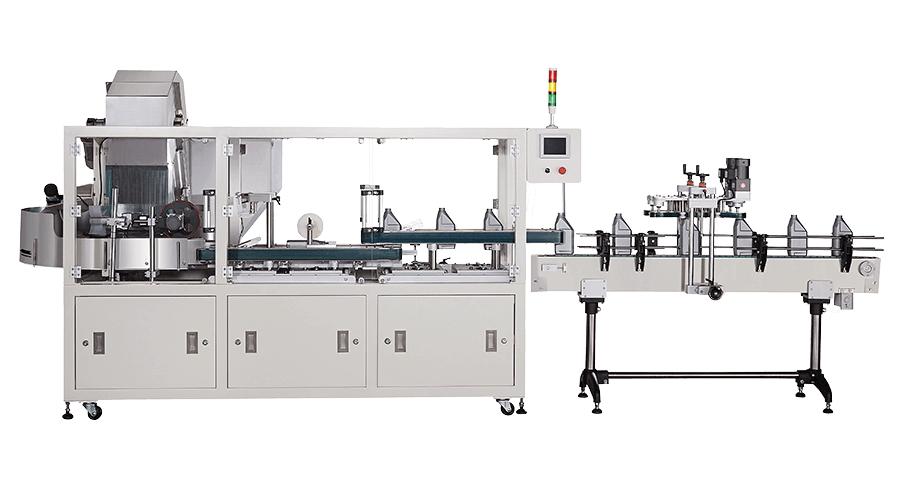

Linear Bottle Unscrambler

Product Introduction

The KWT linear bottle unscrambler is an advanced unscrambler machine designed for feeding oriented bottles into the production line. This bottle unscrambler machine serves as the perfect labor-saving equipment, eliminating the need for employees to manually sort bottles and stand them upright on a conveyor. KWT bottle unscrambler machines are well-built for long-lasting, consistent operation and offer a variety of bottle hopper sizes to suit your specific bottle size range and production speed. The hugger belt & hook system is designed for quick, easy, and repetable changeover. This automatic bottle unscrambler operates with great simplicity, efficiency and minimal maintenance, satisfying the needs of the most demanding customers in the packaging industry.

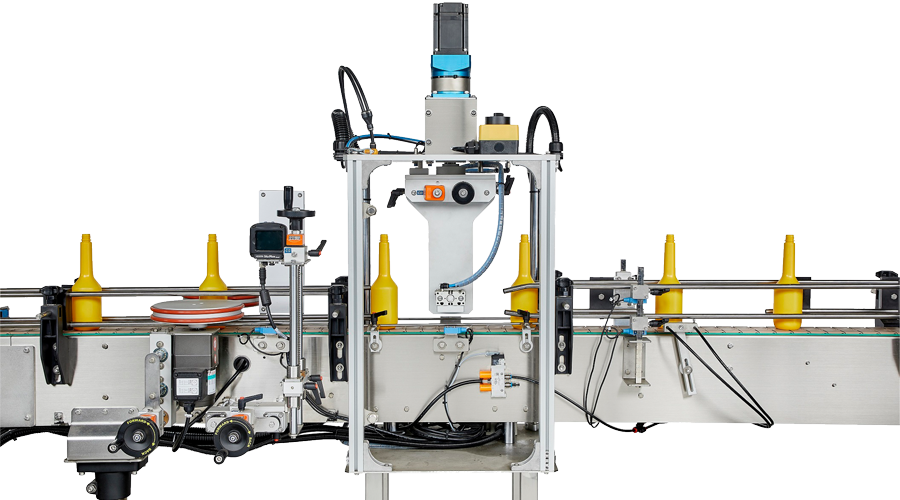

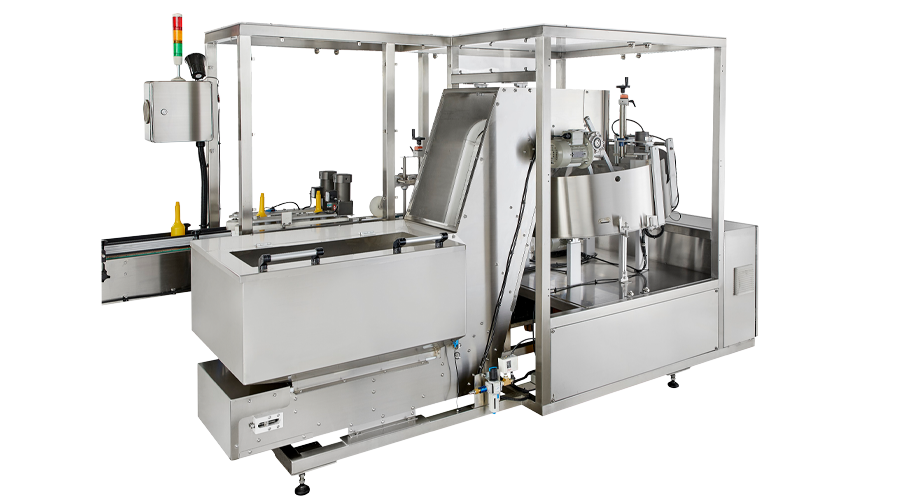

The bottle sorter's operation begins when bottles are loaded into the hopper and supplied to the centrifugal disc through an elevator. In the disc, bottles enter the orientation area, where the bottle handling process begins. Bottles are delivered one by one, and the Bottle Orientaton Hook, acting as a bottle orienter, grabs the neck of the bottles for correcting position. After this orientation process, the upright bottles are stabilized and released on the bottle exit conveyor. The KWT-101A plastic bottle unscrambler is designed to hnadle a wide range of plastic bottles, making it versatile production line equipment. All mechanical adjustments are equipped with a numeric counter for easy and repeatable changes, enhancing the overall packaging process.

One of the primary benefits of bottle unscrambling equipment lies in its flexibility, efficinetly sorting bottles and containers of various shapes and sizes. This container handling capability means that in the even of a need for new bottle sizes, the unscrambler can handle the task without requiring costly new packaging machinery or a reconfigured production line.

The bottle sorter's operation begins when bottles are loaded into the hopper and supplied to the centrifugal disc through an elevator. In the disc, bottles enter the orientation area, where the bottle handling process begins. Bottles are delivered one by one, and the Bottle Orientaton Hook, acting as a bottle orienter, grabs the neck of the bottles for correcting position. After this orientation process, the upright bottles are stabilized and released on the bottle exit conveyor. The KWT-101A plastic bottle unscrambler is designed to hnadle a wide range of plastic bottles, making it versatile production line equipment. All mechanical adjustments are equipped with a numeric counter for easy and repeatable changes, enhancing the overall packaging process.

One of the primary benefits of bottle unscrambling equipment lies in its flexibility, efficinetly sorting bottles and containers of various shapes and sizes. This container handling capability means that in the even of a need for new bottle sizes, the unscrambler can handle the task without requiring costly new packaging machinery or a reconfigured production line.

- Increased Efficiency: A bottle unscrambler automate the process of feeding bottles into the production line, resulting in a significant increase in efficiency and throughput. It can handle a large number of bottles per minute, reducing the need for manual labor and speeding up the production process.

- Improved Productivity: With bottle unscrambling equipment, production lines can operate at higher speeds and maintain a consistent flow of bottles. This leads to improved overall productivity, allowing manufacturers to meet higher demands and deadlines.

- Versatility: Bottle unscramblers are versatile and can handle various bottle shapes and sizes. They can be easily adjusted to accommodate different types of bottles, making them suitable for wide range of products in the packaging industry.

- Integration with Production Lines: Bottle unscramblers are often designed to integrate with other packaging machinery, creating a smooth and efficient production line automation setup.

- Cost-Effectiveness: While bottle unscrambling equipment represents an initial investment, the long-term cost saving from increased efficiency, reduced labor and minimized downtime make it a cost-effective solution for many manufacturing operations.

Integration with existing production lines is a standout feature of this automated bottle handling equipment, making it a preferred solution for various industries including food, beverage, chemicals and household products. The linear bottle unscrambler's ability to enhance production rates and streamline the packaging process makes it an essential piece of production line equipment for businesses looking to optimize their operations.