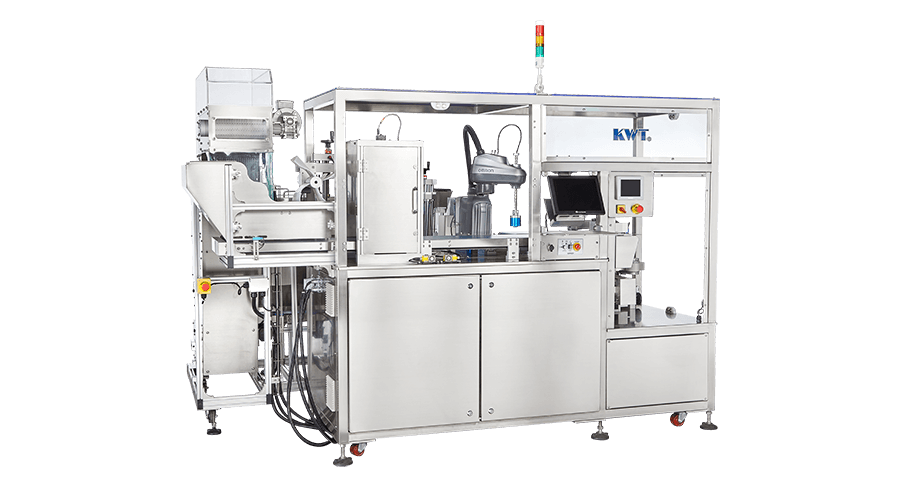

Robotic Bottle Unscrambler

Product Introduction

Discover the cutting-edge capabilities of the KWT Robotic Bottle Unscrambler, a groundbreaking advancement in modern robotics and automation technology. Our latest innovations in robotic bottle unscrambling technology represent a significant leap forward, seamlessly integrating sophisticated tooling mechanisms, advanced vision positioning systems, and precision robot mounting solutions. These enhancements mark a revolutionary step in expanding robotics applications to replace manual operations across various industries. By implementing these state-of-the-art solutions, manufacturers can dramatically optimize their production efficiency while achieving remarkable labor cost reductions. The integration of robotic bottle unscramblers into existing production infrastructure significantly enhances manufacturing flexibility and adaptability.

- Advanced bottle hopper feed system delivers products smoothly to the belt conveyor

- Sophisticated robotic arm paired with high-precision vision system technology

- Intelligent pick and place functionality for precise container handling from transport belts

- Seamless container loading into advanced hugger belt system

Advantage of Robotic Bottle Unscrambler

-

Accuracy: Robotic bottle unscramblers incorporate cutting-edge vision systems and precision control technologies, ensuring exceptional positioning accuracy and optimal bottle orientation. These advanced systems minimize handling errors and maintain consistent performance throughout extended operation periods.

-

Versatility: The sophisticated design of these robotic systems enables them to efficiently handle an extensive range of bottle shapes, sizes, and diverse packaging configurations. This adaptability makes them invaluable assets in modern production environments requiring frequent changeovers.

-

Integration with Other Equipment: These advanced robotic systems are engineered for seamless integration into existing production infrastructure, working harmoniously with other machinery to create a highly efficient and synchronized manufacturing process.

-

Adaptability: The intelligent programming capabilities of robotic bottle unscramblers allow quick reconfiguration to accommodate different bottle specifications or evolving production requirements, providing unprecedented manufacturing flexibility and reducing downtime during changeovers.

-

Labor Savings: Implementation of robotic unscrambler automation significantly reduces manual labor requirements in bottle handling operations, generating substantial cost savings while enabling workforce reallocation to more strategic and value-added tasks.