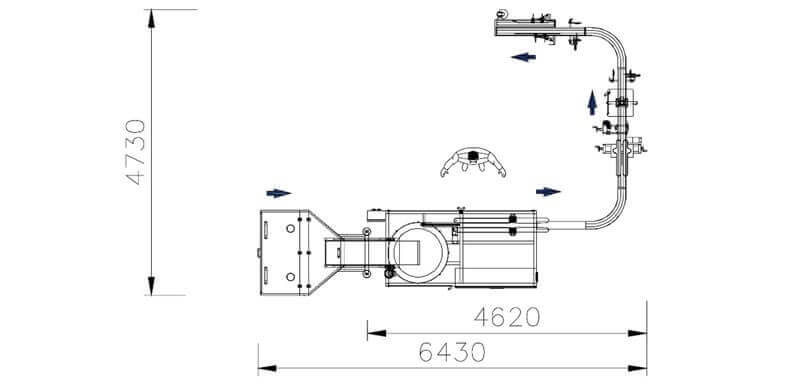

Bottle Unscrambler

Bottle unscrambler is a cost-effective way to easily load bottles on to an automatic bottle filling line, our KWT-101A bottle unscrambler can sort and orient a wide variety of bottles shape and sizes. Bottle are loaded into the hopper, and supplied to the centrifugal disc through an elevator. In the disc, bottles are directed into the orientation area. Bottles are delivered one by one, and the Bottle Orientating Hook grabs the neck of the bottles for correcting position. After that, the upright bottles are stabilized and released on the bottle exit conveyor. KWT has a solution that will make you more productive.

Key Features

- Capable of handling cylinders, squares and rectangles.

- PLC controlled with touch screen panel, easy access to all settings.

- Fast and easy format changes. Operational simplicity – no specialized personnel needed.

- Stainless steel and plastic for bottle contacts.

- Orientation device is designed to orient bottles that have left an unscrambler, using vision system to verify the direction, if bottles must face toward a particular direction.

- Capacity: Up to 80 BPM

Options

- Safety Guard

- Sorter disc for different size of bottle

Specifications

| Capacity | 60-80 BPM |

|---|---|

| Bottle Thickness | 35~80mm |

| Bottle Length | 40~135mm |

| Bottle Height | 130~250mm |

| Machine Size | L.2866 x W. 3059 x H. 2048mm |

Video