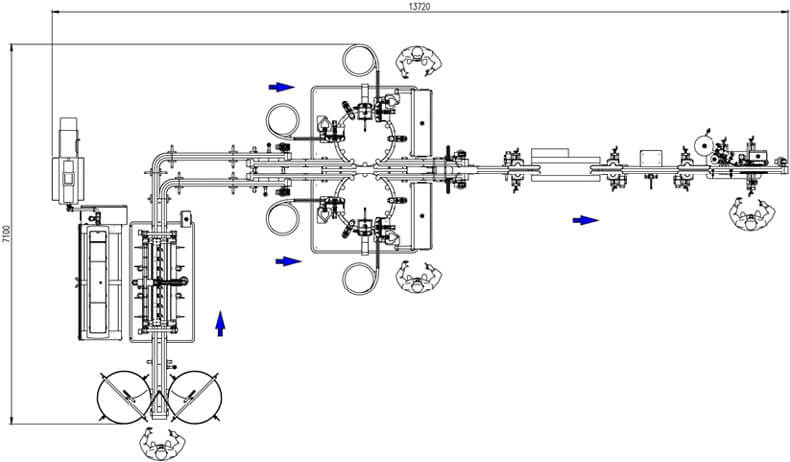

Dual Lane Facial Gel Filling Line

Filling Range

200ml-1000ml

Nozzles

8

Speed

≦60 pcs/min

A full line for bottle filling, capping and labeling for lotion, conditioners, cream and any other medium to viscous product . KWT volumetric piston pump works with various types and shapes of bottle, 8 filling nozzles in dual lane ensure continuous work without stop for saving the waiting time. Dosing range is from 200ml to 1000ml, the productivity up to 60 pcs /min.

Key Features

- Piston pump is suited for viscous product.

- Robust construction in stainless steel.

- Mitsubishi PLC controlled with touch screen panel.

- Easy adjusting hand wheels for quick changeover.

- 50 job memory for easy set-up and recall.

- Neck grabber for different sizes of container.

- Capable capping type: plastic screw cap.

- Auto Pick & Place device is designed to handle most cap types, and driven by servo motor.

- Capping chuck with servo drive for adjustable torque values.

- Labeling – automatic labeling machine to label cylindrical containers (wrap-around).

Options

- Filling Machine

- Safety Guard

- Nozzle up & down action driven by servo motor

- Bottle Feeding Turn Table

- Capping Machine

- Safety Guard

- Cap hopper & elevator

- Vibrator bowl, cap chute, gripper and chuck for different size of cap

- Bottle star-wheel for different size of bottle

- Inspection: missing cap

- Labeling Machine

- Coding system: hot stamp or thermal-transfer printer

- Missing Label Detector

Specifications

| Nozzles | 8 nozzles in dual lane |

|---|---|

| Fill Volume Range | 200ml-1000 |

| Filling Pump | Piston Pump |

| Nozzle Size | Dia. 32mm |

| Container Diameter Range | 50mm-90mm |

| Container Height Range | 120-200mm |

| Capping Machine | 182AS x 2 |

| Label Type | Pressure Sensitive Label |

| Label Size | 20-180mm in height, 20-250mm in length |

| Label Roll Size | I.D. 76 mm , O.D. 350 mm (Max.) |

| Conveyor Width | 82.5mm |

| Conveyor Length | 13,720mm |