2026 Technical Framework: Optimizing Automatic Liquid Filling Systems

In the modern manufacturing landscape, efficiency and precision are no longer just goals—they are the bedrock of operational scalability. For sectors such as food and beverage, chemical, and cosmetics, a fully integrated Automatic Liquid Filling Line acts as the synchronized heart of the facility.

Transitioning to a high-performance automated system does more than accelerate output. It establishes a controlled environment that eliminates human error and minimizes material waste.

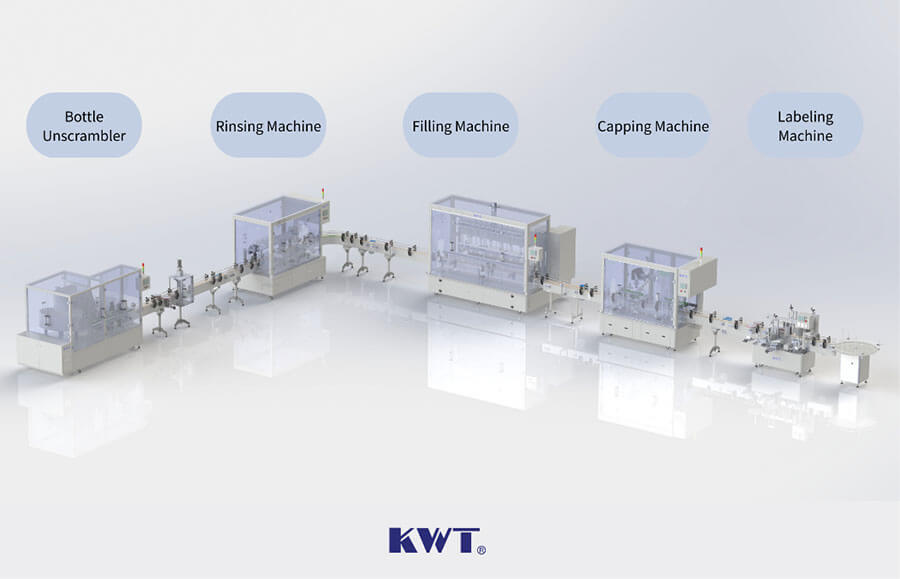

The 5 Essential Pillars of a Professional Packaging Ecosystem

1. Engineered Order: Intelligent Bottle Unscrambling

Every high-speed process begins with organization. Bulk-fed containers are typically disorganized when introduced into the system. An Automated Unscrambler utilizes mechanical orientation to stand containers upright and aligned—neck-up—before they enter the primary conveyor. This critical first stage ensures that every downstream module receives containers in a uniform manner, preventing the costly downtime associated with jams.

2. Purity Assurance: Advanced Rinsing Technologies

Before any liquid enters the container, the interior must be pristine to prevent contamination. Modern rinsing units utilize ionized air or clean water to neutralize static and remove microscopic debris. For hygiene-sensitive industries like cosmetics or food, this step is non-negotiable. Sustainable systems now integrate "No Bottle, No Rinse" sensors to optimize water and energy consumption.

3. Precision Filling: Selecting the Right Volumetric Technology

The filling station is the technical centerpiece where product integrity is maintained. The choice of technology depends heavily on fluid dynamics and viscosity:

- Piston Pump Systems: Engineered for high-viscosity fluids (sauces, heavy creams) or liquids containing particulates. They work like a large syringe, drawing a precise volume into a pump before dispensing it into the container.

- Flow Meter Technology: A hygienic, low-maintenance choice for conductive liquids. By utilizing magnetic or mass flow sensors, these systems offer rapid changeover capabilities with minimal contact parts.

- Net Weight Filling: Each bottle is weighed in real-time on a load cell during the filling process, ensuring the final product reaches the exact target weight regardless of density changes.

4. Absolute Integrity: Automated Capping and Sealing

Once filled, the containers must be sealed immediately to prevent contamination or leakage. The Capping Machine automatically pick up a cap, pleases in on the bottle and applies the correct amount of torque to tighten it.

5. Compliance and Data Integration: The Final Stage

The Auto Labeling Machine provides the final layer of market readiness. Modern labeling stations do more than apply graphics; they integrate with sensors for placement verification and inkjet printers to add real-time traceability data, such as lot numbers and expiry dates. This ensures the product is both shelf-ready and compliant with international regulatory standards.

Strategic Evaluation: Why Automation Dictates Growth

Integrating these distinct modules into a seamless flow allows manufacturers to achieve three strategic advantages:

- Labor Optimization: Shifting the workforce from repetitive manual tasks to high-value quality oversight.

- Predictable Throughput: Eliminating the fluctuations of human fatigue to maintain a constant, measurable production rate.

- Enhanced Safety: Safety guard and automated handling protect the product from environmental contaminants and reduce the risk of workplace injuries.

Industrial Application Audit

Identifying the right configuration depends on your specific sector requirements:

- Food & Beverage: Prioritizing "Easy-Clean" designs and precision dosing.

- Cosmetics & Personal Care: Focusing on various and delicate bottle handling.

- Chemicals & Lubricants: Requiring robust and durable.

For a detailed technical assessment of how these systems can be tailored to your specific production goals, visit our Technical Resource Centre or consult a KWT automation specialist.