Cooperating with Form-Fill-Seal vertical packaging machine

When I saw the advertisement in Dubai airport , Every camel has its story. Like the lightning strikes on my head , there is a new slogan , Every machine has it story , was flashed on my brain. The following is the story about labeler cooperating with FFS packaging machine.

Customer packages the car parts or hardware by manually and usually use zipper storage bag. But , the costly zipper storage bag is a very heavy pressure of cost. Also , operate need to prints product description label , which is including 3 kinds of language discretion and bar code , then stick onto plastic bag.

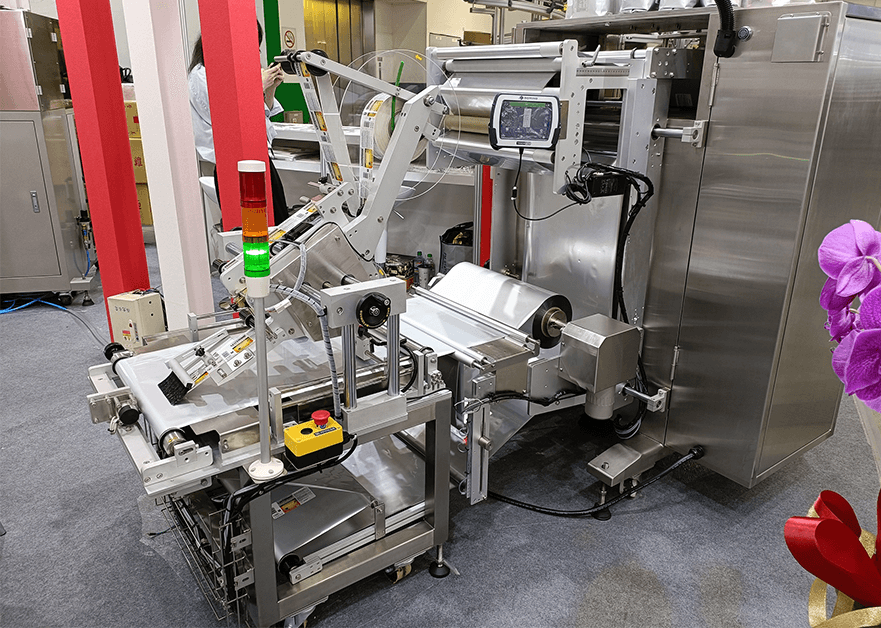

Just like Ethan Matthew Hunt at the beginning of move , Mission Impossible, colleting his teammate , after considering all of demands from client , my team decides to utilize.

- Parts transporting conveyor with cup.

- Form – Fill – Seal vertical packaging machine with PE film , provided by Yueh Chyum Machinery Co., Ltd.

- Top applicate with adhesive label in roll form provided by KWT Machine Systems Co., Ltd.

- Thermal transfer printing engine provided by Domino Taiwan.

- Final products transporting conveyor.

For achieving customer's requirement , a complete packaging line and reduce the cost of packaging material.

KWT ever sold the same concept production line to Hwa Yuan Foods Co., Ltd. several times before , it seems that no challenge / no big issue in this project. All machines are sent to KWT on initial schedule. Perfect , but...

The machine of Hwa Yuan is continuously removing the packaging film , and the machine of current client is intermittently removing the packaging film , thus how to control the tension of film is the major point. Till we process the long run test , then find the big issue. If we can't control the tension of film properly , the labeling accuracy will be very very bad. We don't become aware of the different type , continuously & intermittently removing packaging film , that causes we make the huge mistake when we design the machine.

Spending one week for various testing , we modify the film tension controlling system , and add the additional supporting rollers , improve the removing film system , also the path of inserting film. Yes , the big issue is solved. The labeling accuracy is good , the packaging result is nice. We can deliver the machines to customer's side. And this story has a happy ending.